Guest post is provided by Denton Vacuum, LLC, a leader in processes such as magnetron sputtering and PVD coating. Browse their website for more information.

Thin film technology and vacuum metallization are used in a variety of uses. These technologies are used in a variety of industries including medicine, solar, optics, microscopy, semiconductors, aerospace as well as other emerging technologies.

Both thin film technology and vacuum metallization have a wide range of modes. When these processes are mentioned, it’s crucial to discuss physical vapor deposition. Physical vapor depositions occur in a high precision vacuum. PVD uses a thin layer film and places it onto a substrate. This process doesn’t involve a chemical reaction, but is solely a physical process. PVD is just one of the popular types of vacuum deposition systems that are widely used.

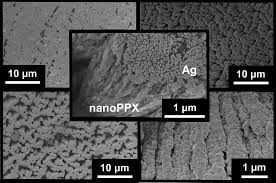

One of the biggest advantages to the diversity in thin film technology is the contribution it has made to the medical field. Magnetron sputtering systems and ion beam etching are two of the most commonly used methods in the creation of medical devices. The magnetron sputtering system is one such process that uses magnets to stabilize a charge while performing physical vapor deposition. Essentially, a target material is vaporized and then leaves behind a thin film on a substrate. These films are then used in the coating and manufacture of many different types of high-tech products, including medical devices.

With the production of the various medical devices, people’s lives all over the world are benefitting from these new technologies. Medical devices span a wide range of uses and applications such as wheel chairs, pacemakers, MRI devices, as well as optics.